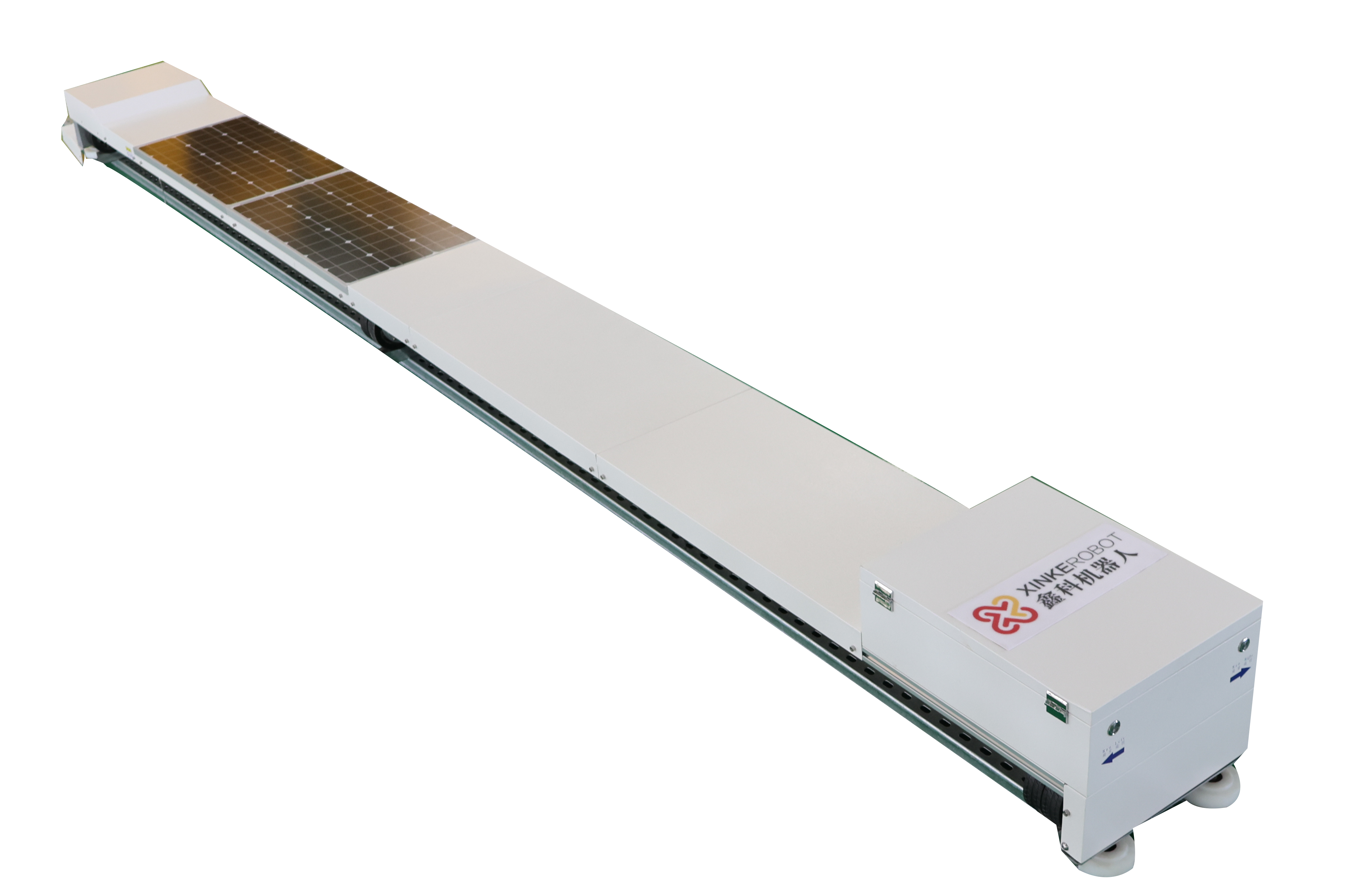

crawler inspection robot

In terms of remote inspection technology, the crawler inspection robot represents the most advanced achievement. It can conduct a detailed examination even in environments that would say "impossible". So its main functionalities are visual checking, measurement, and the discovery of anomalies in structures and systems. Equipped with advanced sensors, high resolution cameras and powerful illumination systems, this robot can operate in spaces that are dark or too small for human inspectors to visit themselves. Wireless communication, automated navigation features and a modular design help the robot incorporate cutting-edge technologies into a wide variety of industries. From pipelines and nuclear facilities to bridges, crawler inspection robots make maintenance easier and safer.