- Overview

- Related Products

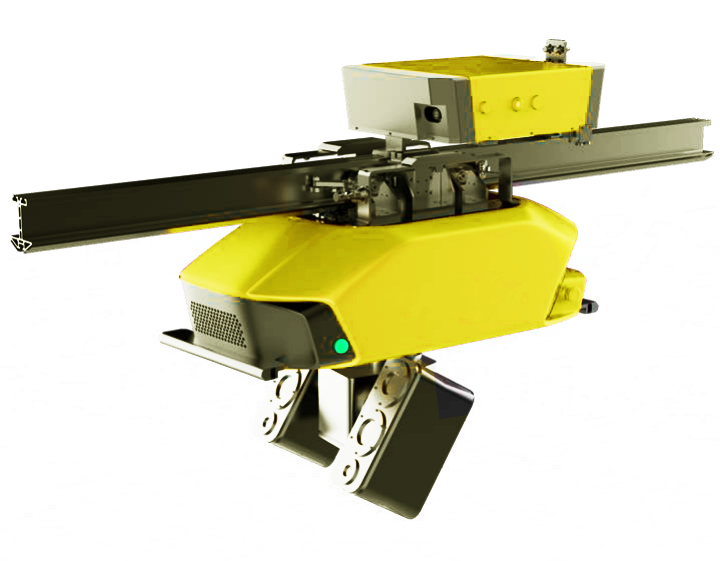

Product Overview:

The explosion-proof wheeled inspection robot is mainly composed of robot body, wireless base station, autonomous charging device and remote control station. Widely used in Class II explosive environment, it can replace inspection personnel to carry out equipment and environmental inspection, which can reduce the labor intensity of inspection personnel, reduce the security risks existing in the inspection process, improve the inspection quality at the same time, and maximize the essential safety level of petrochemical enterprises.

Product features:

Drip detection function

Combined with gas detection sensor and intelligent identification algorithm detection technology, flammable and explosive gas leakage detection is realized. Based on the fusion detection technology of image processing and deep learning, according to the image characteristics of liquid leakage, the leakage in key areas of the pipeline can be accurately detected.

Video analysis function

Intelligent analysis of on-site instruments, valves and other equipment according to user requirements.

Audio analysis function

According to the requirements of users, the field cylinder, oil pump, motor, bearing and other equipment audio analysis and early warning.

Temperature collection and analysis function

It can realize the temperature status identification, analysis and judgment of equipment, pipelines and key components, and timely alarm of high and low temperature anomalies; Temperature imaging features are used to detect temperature trends of key components through different time nodes.

Head lifting function

The robot automatic safety cloud platform can realize automatic lifting, improve the robot inspection adaptability and inspection quality.

Intelligent collision avoidance, anti-fall and autonomous obstacle avoidance function

The infrared obstacle avoidance and anti-fall detection system with high stability can automatically stop and alarm when encountering obstacles and descending steps to prevent personnel and equipment damage caused by collision.

Intelligent voice prompt and two-way voice intercom function

If the robot inspects anomalies or its own anomalies, it can prompt the user to deal with them by voice; Two-way intercom function can realize remote command field operators work.

Data archiving and historical query function

The monitoring platform will automatically archive the abnormal information or its own faults found by the robot inspection operation and can be viewed at any time.

Multi-angle fill light

It is equipped with light filling equipment to meet the demand for light during robot inspection, and provide guarantee for robot all-weather and multi-scene application.

Supports mobile control

Provide APP control terminal, remote data presentation and robot remote control through mobile phone and tablet APP. More user-friendly platform software, so that the operation is simple and efficient.

Product advantages:

● With the lifting function of the cloud platform, it can meet the data acquisition requirements of different observation points and has high flexibility;

● With high-precision navigation system, can carry out autonomous navigation, high-precision inspection;

● The explosion-proof modular wheel drive system can adapt to a variety of ground environments, especially to extremely complex unstructured terrain, such as sand and gravel pavement, shock belt pavement, etc.

● High-power, four-wheel drive design to meet the walking requirements of robots in complex road conditions;

● With intelligent identification and analysis system, through intelligent identification algorithm, to realize the analysis and identification of instruments, positions and equipment status, to help users quickly and accurately grasp the field conditions;

● Modular design, easy to expand, can be equipped with a variety of detection sensors to meet different field needs;

● The robot has its own power detection and self-charging functions;

● The robot supports 4G/5G/Wifi multi-network mode communication.