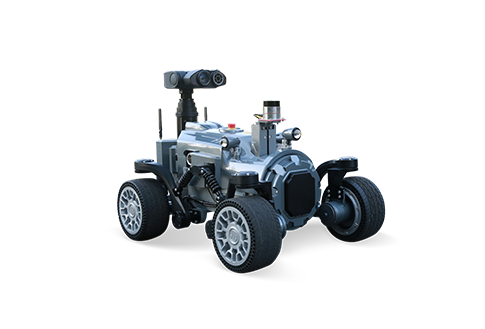

Smelting Inspection Robot

- Overview

- Related Products

Product Overview:

The smelting inspection robot is mainly used for the inspection of the bottom of the electrolytic cell, and can replace the inspection personnel to collect and analyze the temperature of the side, cathode steel rod, tank bottom and bus bar. Determine the abnormal situation by the temperature trend, and conduct real-time early warning to effectively prevent accidents.

Product features:

Temperature collection and analysis function

Using thermal imaging non-contact temperature detection, it can accurately detect the temperature value of the cathode steel rod, side, groove bottom and other important equipment, and automatically alarm if the temperature is abnormal. Historical temperature data is used to plot temperature trends and analyze equipment conditions according to temperature gradient changes.

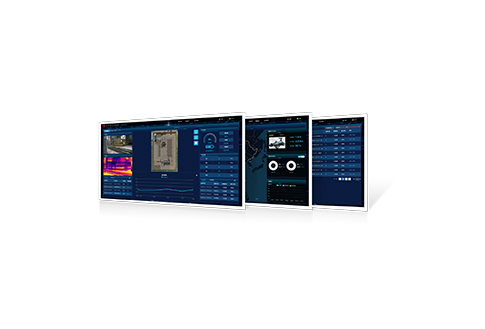

Data query function

Robot inspection real-time status, history record, abnormal record and other information, through the host computer can be queried.

Autonomous navigation function

Accurate navigation and positioning can realize automatic identification and positioning of detection targets, and multiple inspection routes can be combined freely.

Automatic charging function

After the robot completes the inspection task, it can automatically find the charging pile to charge.

Image acquisition function

Special binocular vehicle ball machine, 360° all-round, no blind spot intelligence monitoring.

Autonomous obstacle avoidance function

The robot obstacle avoidance system can intelligently perceive the distance contour of obstacles, and has the characteristics of large viewing Angle, fast response and high sensitivity.

Audio Analysis function (optional)

By collecting onsite sounds, the system intelligently analyzes abnormal sounds and automatically prompts for fault detection.

Environment detection function (optional)

Modular design, easy to expand, can be equipped with a variety of detection sensors to meet different field needs.

Product advantages:

● Anti-magnetic, high temperature, dust proof design, can adapt to potholes, gravel and other complex pavement;

● Non-contact temperature detection using thermal imaging, large-area temperature measurement automatically captures high temperature points;

● Using the most advanced 3D laser navigation technology, to meet the robot climbing, narrow space and other complex environment use;

● With self-test and protection function, to ensure the safety of robot application;

● By adding preheating system inside the robot body, it can meet the ultra-low temperature -35℃ environment;

● Modular design, easy to expand, can be equipped with a variety of detection sensors to meet different field needs;

● Binocular vehicle ball machine, to achieve all-round, no blind spot intelligent monitoring;

● The video and data collected by the robot body can be transmitted stably and reliably through private encryption protocols, effectively improving the anti-electromagnetic interference;

● Intuitive operation interface, simple control, easy to learn and use;

● Meet the all-weather operation requirements of the robot.