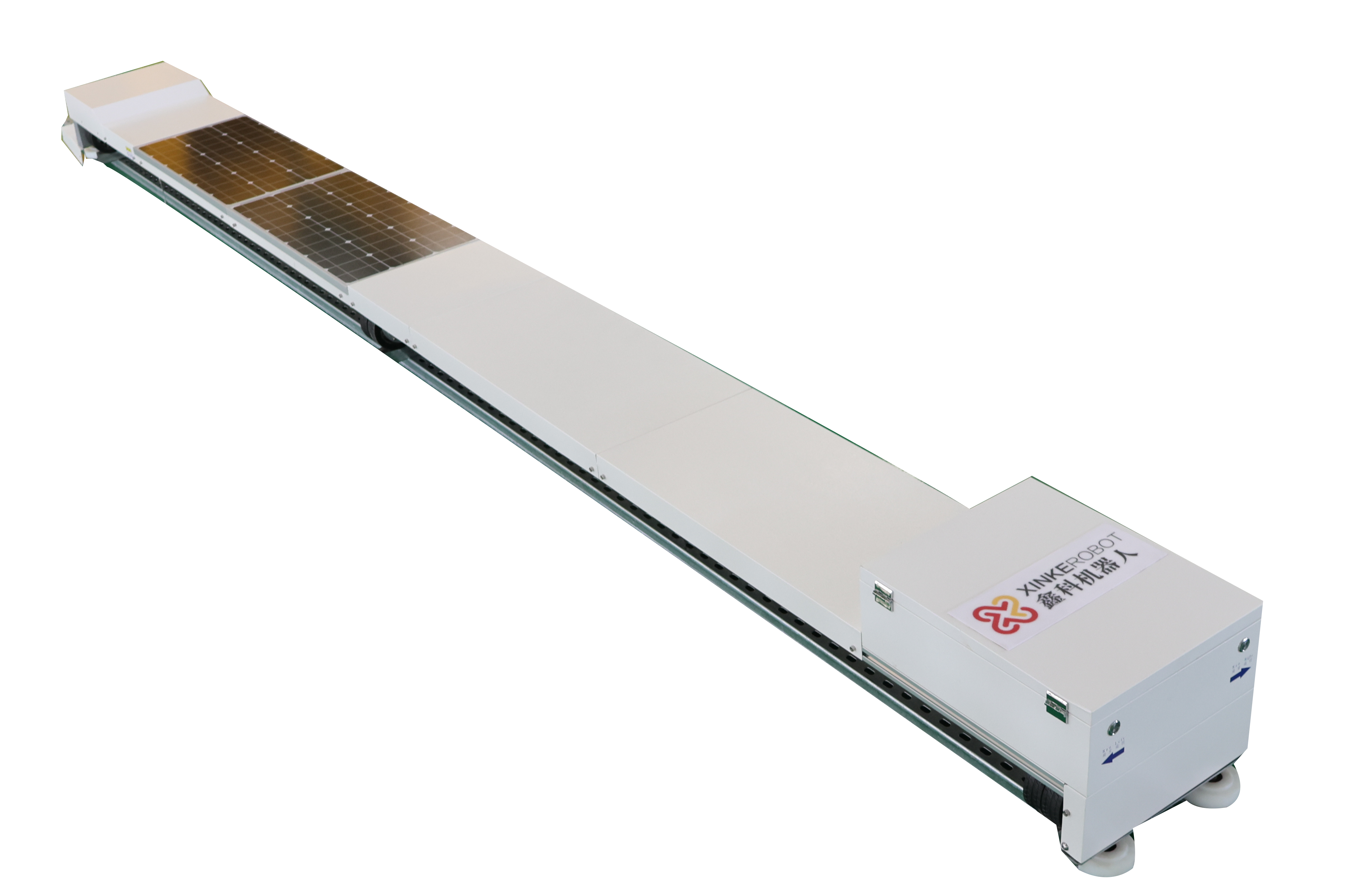

internal pipe inspection robot

The internal pipe inspection robot manages to find its way through pipeline mazes, climbing up long pipes and riding under rivers in order to get an objective picture of them. It patrols the length of pipe checking for leaks, corrosion and blockages - structural trouble that is indiscernible to our unaided human eyes. The robot sees the inside of the pipes in high resolution pix its advanced camera system turns out and also measures helpful data. Its modern features, like automated navigation systems, wireless communications, and robust construction enable the robot to run through pipes of all sorts- no matter their diameter or what they are made out until it works properly on this vast array.Industry clients for the robot include manufacturing oil and gas industry, water management systems, where it is used to maintain the infrastructure s health and prevent costly damages to a multitude of industries.