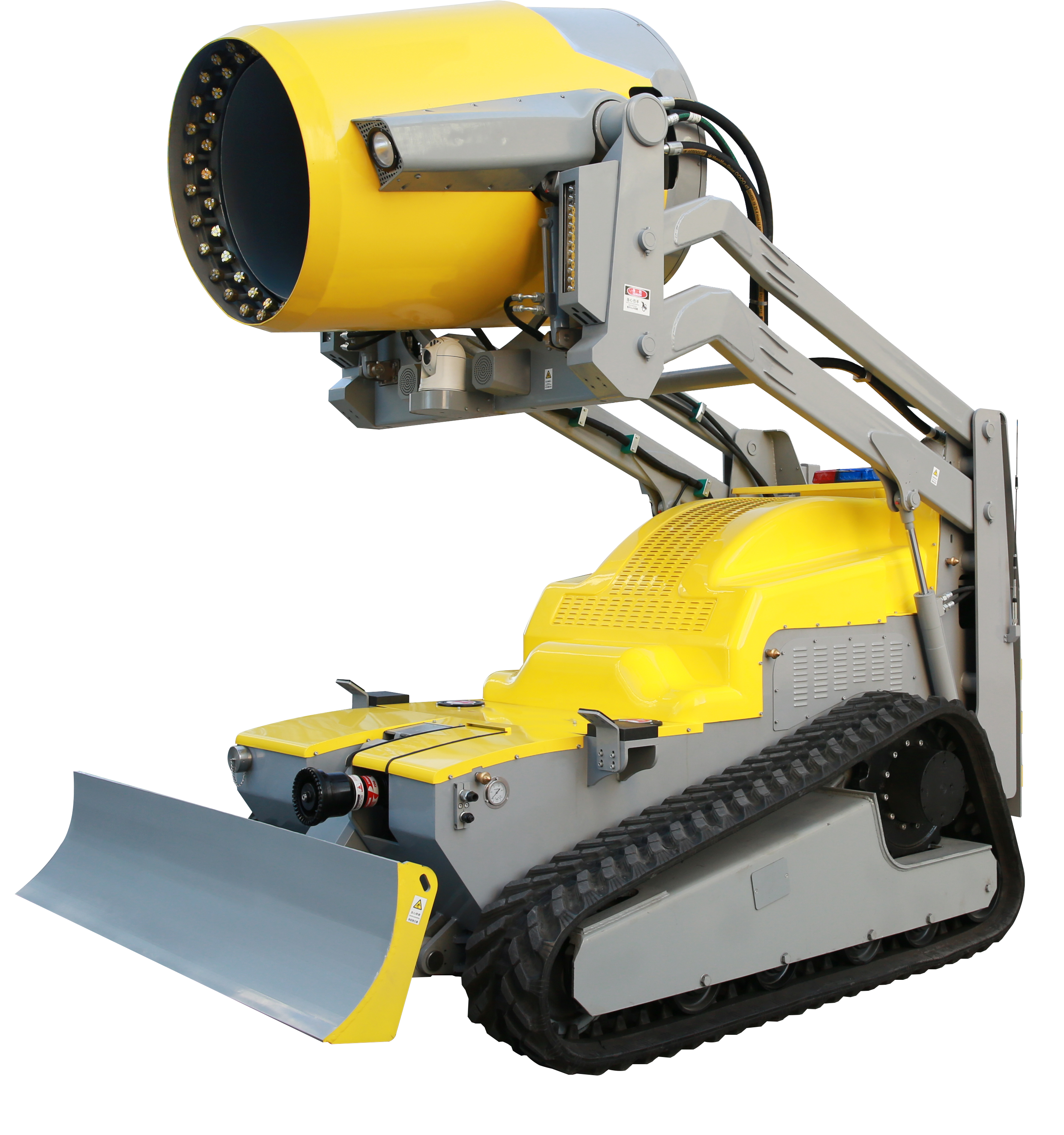

portable welding robot

The future of automated and accurate welding is present in the portable welding robot.Limp, compact, and convolutedly programmed, it can accomplish such functions as arc welding, resistance spot welding, and butt seam welding.These advanced machines are equipped with precision sensors and an easy-to-use touch screen. They operate independently, tooFor a variety of industries, this revolutionary robot can be used. Including auto manufacturing, the airsphere (aeronautics), and various other construction tasks, it suits all sorts of jobs. Moreover, when it is hard to weld precisely or if welding is going particularly bad--The productiveness goes way up.