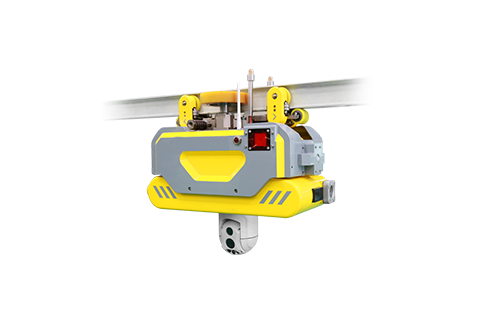

GLXJ-48 Comprehensive Pipe Corridor Inspection Robot

- Overview

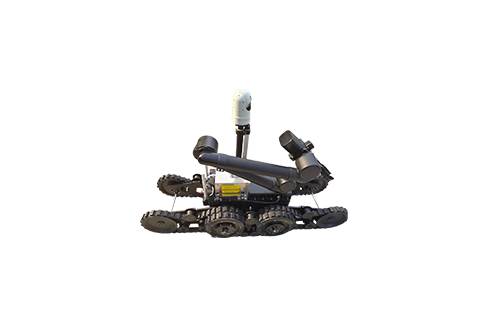

- Related Products

Product Overview:

The inspection robot system is composed of inspection robot, track platform, power supply platform and communication platform. The inspection robot, combined with the remote monitoring platform, data server and related accessories, can realize the uninterrupted intelligent inspection of the integrated pipe corridor environment and equipment.

Product features:

Instrument identification function

If there is an instrument installed in the field, the inspection robot can separate the background and the target in the scene through computer image vision analysis technology, analyze the target appearing in the camera scene, and intelligently recognize the instrument reading.

Field environment detection function

The robot is equipped with environmental detection sensors, which can real-time monitor the on-site temperature and humidity, harmful gas content, air oxygen content, smoke concentration and illumination, and can realize the detection of lighting and manhole cover in the comprehensive pipe gallery.

Image acquisition function

The anti-jitter visible light video monitoring and thermal imaging monitoring based on the omnidirectional head can realize the video inspection and infrared temperature measurement of the integrated pipe corridor.

Interactive intercom command function

Through high-gain pickup and HD camera, the platform can exchange audio and video information with field personnel.

Intelligent collision avoidance and autonomous obstacle avoidance function

Using infrared obstacle avoidance sensor, automatically stop when encountering obstacles, and alarm to prevent collision caused by personnel and equipment damage.

Attitude analysis function

Independently judge the pitch Angle of the pipe gallery and automatically adjust the running speed.

Automatic alarm function

When the robot finds anomalies or has problems itself, it can make sound alarm through the upper computer.

Product advantages:

● The operation mode of robot hanging on the track does not occupy ground space and does not affect pedestrians;

● Reciprocating inspection of the integrated pipe corridor, real-time collection of the integrated pipe corridor status information and storage;

● The robot quickly locks the fault point through its own encoder and automatic mileage calibration;

● Distributed charging station + battery power supply mode: distributed charging station

● Use contact anti-ignition safe charging technology, safe and reliable; The robot can cooperate with the charging equipment to complete the autonomous charging;

● Can access the industrial Ethernet ring network to realize remote monitoring of equipment in the scheduling room.